Concrete Mixing Bucket - Loader

The Concrete Mixing Bucket serves as an incredibly handy device for mixing concrete using a loader.

Read moreConcrete Mixing Bucket - Excavator

The Concrete Mixing Bucket serves as an incredibly handy device for mixing concrete using an excavator.

Read moreConcrete Mixing Bucket - Agro

The Mixing Bucket - Agro Version: Designed with front & rear three-point tilt connections for superior concrete mixing with tractor.

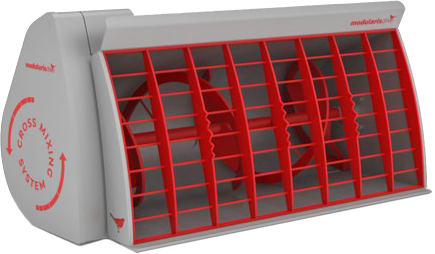

Read moreMODULARIS CROSS MIXING SYSTEM®

Deliver significantly higher concrete quality with our patented innovation – the Cross Mixing System®, which allows for more rapid and even mixing across the entire bucket.

30% SHORTER MIXING TIME AND 30% LOWER FUEL CONSUMPTION

The innovative spiral mixing element pushes the concrete mix in all directions. This technique allows for high quality mixing in a significantly shorter time and reduces fuel consumption.

“It’s been 20 years since I first bought a Modularis concrete mixing bucket. The bucket is still working safely and reliably.”

Vinko Pirc

3-YEAR WARRANTY

Premium Quality and Durability

Modularis mixing buckets are made of high-quality components:

- MS hydromotors for the toughest work conditions,

- abrasion resistant Hardox and Sidur steel, and

- a reliable seal and bearing lubrication system.

All this combined guarantees top performance and durability, which is backed by a 3-year warranty.

20+ YEARS

GRADBENIŠTVO GOTOVNIK

“We own around 5 different models and all of them are easy for use and maintenance.“

– Ožbej

> 1000 M³ OF CONCRETE

TGM VIC

“It’s been over 6 years now and it still works flawlessly like a swiss watch.”

– Jure

NO DAMAGES

JOŽE LUZAR

“We have been using the mixing bucket for over 15 years and I would say it is practically indestructible.”

– Jože

THINK RATIONALLY AND SUSTAINABLY

The cross-mixing system significantly increases the mixing speed and productivity and reduces fuel and labour costs.

For instance, in the production of 1000 m³ of concrete, you save up to 200 litres of fuel and 200 hours of labour. Over two decades, our technology has saved users 9,000,000 hours of labour and 9,000,000 litres of fuel.

CROSS-MIXING® IN ACTION

SUPERIOR QUALITY OF CONCRETE READY IN JUST 2 TO 3 MINUTES

SUITABLE FOR A WIDE RANGE OF HEAVY MACHINERY

TELESCOPIC HANDLER

BACKHOE LOADER

SKID STEER LOADER

FAQ – Frequently asked questions

Mixing concrete or other mixtures is executed by rotating the mixing element (i.e. the spiral or screw thread), which is fitted in the body of the bucket. The rotation is carried out by a hydraulic drive via a chain transmission, which has been proven to be the most reliable, efficient and safe and requires no special maintenance. The sand or compound is first scooped by the machine and then cement and water are added manually or from a silo while the mixing element is rotating.

Request a quote

Do you need more information about specific product?

Contact us.